'Pre-WCCA' Design Review

Our pre-WCCA circuit design review identifies design issues and possible non-compliances

that would likely arise during the execution of a worst case circuit analysis. The

review eliminates design issues and highlights WCCA findings early on so they can

be fixed when there is time, saving you budget and schedule.

AEi Systems brings decades of WCCA experience to bear on finding problems in analog,

digital, and RF circuitry. We highlight the potential and certain worst case failures

allowing you to fix them before the formal WCCA is performed. We review vendor supplied

simulation models in order to determine which ones are adequate (usually very few)

and what their flaws are. We determine which circuit tests should be performed in

order to support the WCCA, models, and circuit correlation and verification. We

develop a WCCA plan and help you save money by prioritizing and/or eliminating unnecessary

and costly analysis. We guide you by reviewing flow-downs and guidelines and making

sure you do only the analysis that is value-add and required.

“The pre-WCCA design review is one of AEi Systems most valuable services.”

-- Dave E., Ball Aerospace

The review produces:

- A WCCA plan

- A budget and schedule

- Prioritized list of analyses and analysis recommendations that should be performed

- A review of the key analysis guidelines and what they mean to your design and organization

- Resource definition: who needs to perform the analysis and what skills they should have

- Lists of models that are needed for the analysis including what model characteristics must be correlated

- Test data necessary to correlate models

- Suggested test point list to support the design, findings and WCCA

- Tolerance Database including a list of aging and radiation tolerances needed

SAMPLE ANALYSIS FINDINGS

- Hard to see End-of-Life, Temperature, and Tolerance Stack-up issues

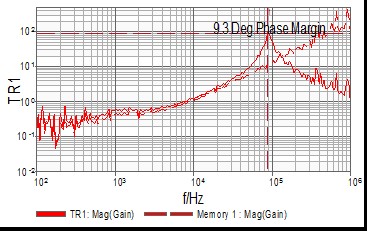

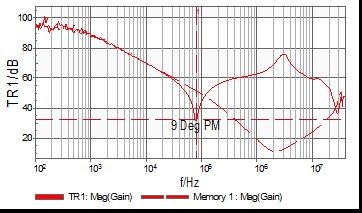

- Regulator Violations: Stability, Latch-up, Headroom, PDN, Loading and Compensation

- Opamp Violations: Stability, Common-Mode

- Bad SPICE Models

- Relay Usage and Cross-Strapping Violations

- Erroneous data sheet data

- Incorrect Decoupling

- Inadequate Interfaces: 1553, LVDS, Board-Board

- Logic Compatibility, Termination, and Un-used IC Violations

- SSO and Package Parasitics Issues

- BJT/FET Leakage/min hFE, SOA

- Power Sequencing Violations

- Layout and PDN Violations

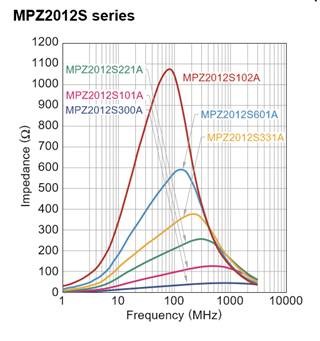

- Filter/Bead Q Stress Violations

- Stress Items: Over-stress Conditions, Pulse resistors, IC Violations

Getting your own data is essential to filling in the holes. Manufacturer EVMs are

often inadequate. Custom test boards often have to be built.

- Find Outages and WCCA Findings BEFORE the formal analysis process

- Help eliminate design issues before they become problems

- Save time and money by eliminating costly WCCA findings

- Highlights issues so that fixes can be applied early

- Vet bad manufacturer reference design recommendations

- Reduce Board Spins

Design Review Activities

- Prepare your organization for a WCCA and Stress analysis

- List circuit concerns along with rationale

- Recommend bench and component tests to support findings

- Develop a system test point list for use in WCCA and model correlation

- Identify design issues; both potential and actual

- Identify where worst case analyses may have findings

- Identify test and component data needed to perform a WCCA; list impediments

Bead Impedance must carefully evaluated and properly decoupled

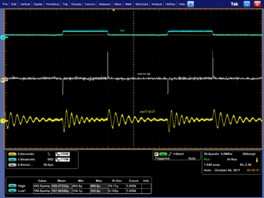

Unstable REF-02 voltage reference. Despite the manufacturers recommendation to include

a 0.1uF output capacitor, the result is unstable.

Analysis | SPICE Modeling | Publications

Home | Services |

About Us | Contact Us | Jobs

Terms of Use | Site Map

©AEi Systems, Inc. All Rights Reserved.